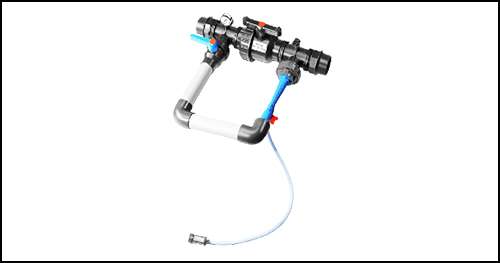

What is Venturi Manifold?

Venturi Manifold is a complete assembly with ball valve, pressure gauges, and venturi injector and is installed directly in the irrigation system. With minimal user effort, it is the best irrigation system to inject herbicides, chemicals & fertilizers by creating pressure differential through ball valve at venturi injector inlet and outlet pressure.

Benefits of Automat manufactured Venturi Injectors:

- Requires low-pressure differential as compared to other venturi injectors available in market.

- Starts suction at best 25% or less pressure differential.

- Local venturi injector starts working within pressure differential of 50% to 75%.

What difference it will make to Farmers?

- Less throttling of pipe in Automat venturi manifold as compared to other local brands

- In Automat venturi manifold system pressure reduces only 25%, which does not affect any major performance of sprinklers or drip irrigation or crop yield.

- Whereas in local venture injector system pressure reduces to 50% which affects the performance of drip and sprinklers and reduces crop yield.

What is the impact of less pressure differential of AUTOMAT venturi injector??

- Because of less system pressure loss, a 10-15 % more area can be brought irrigation/fertigation.

- Even distribution of fertilizers in the field causes no damage to the crops. This results in improved crop yield by up to 5% as compared to local venturi injector.

Economics:

Impact of Less Pressure differential

- With Automat venturi injector, the cost of drip irrigation system is reduced by nearly 4 – 7% as compared to irrigating the same area by local venturi injector.

- The less area to be irrigated by local venturi injector leads to more drip section for irrigation/fertigation.

- To irrigate the extra drip irrigation section, the system running cost is increased.

Thus, approximately 1000-1500 INR is saved by covering more area in less time.

Impact of Non-uniform Fertilizer Distribution

- With Automat venturi injectors, a farmer gets 15T onion crop yield in a 1-acre field.

- By reducing 5% onion crop yield from 15T, the reduced yield is approximately 300 kg.

- The cost of 300kg onion is approx. Rs. 2000/- (As per farmers cost price)

Thus saving on INR 2000 by taking a full yield

The life of Automat venturi manifold is a minimum of 3 years. It is a cost-effective, long term expenditure as compared to a local venturi injector which is high on installation cost and regular assembly damage fixes thereby making it more expensive than a one-time investment in Automat’s Venturi Manifold.

| Parameters | Automat’s Venturi Manifold | Local Venturi Manifold |

| Lifespan | 3 to 5 years | Up to 1 year |

| Raw Material | Polypropylene Glass Reinforced material | Low grade ABS/PP/second-grade material |

| Fertilizer Injection Strength | No reduction in the fertilizer injection strength in the long run | Fertilizer injection strength reduces by 2 to 3 times |

| Distribution | Uniform distribution of fertilizers & chemicals that covers more area | Non-uniform distribution of fertilizers that covers less area |

| Crop Yield | More crop yield | Less crop yield |

| Cost | One time investment, no hidden loss in the usage and long run | Recurring expenditure, hence not cost-effective |

| Efficiency | Saves energy, manpower and labor | Requires more energy and is labor-intensive |

The farmer is not able to assess the hidden losses borne by him upon purchase of a local venturi but ultimately he will stand to benefit more by the purchase of Automat Venturi and its complete assembly.

He can easily calculate the rate difference in the first year of crop yield and can smoothly run the Venturi Manifold injector assembly without any trouble for good three years.