Overview:

The radical changes currently being undertaken in agriculture irrigation throughout India due to the drought, ground water level and climate change, have opened a window of opportunity for a new franchise group in the water sector.

“Indians are now realising the true value of water, and are investing heavily in agriculture irrigation systems that use it more wisely. Think water has formed to meet that demand.”

Water filtration is very important to almost every irrigation system. When purchasing a pressurized irrigation system, such as a sprinkler or drip/micro system, one of the primary decisions to make is which filter to use. Aside from the obvious cost factor, the type of filter you choose will primarily depend on the emission device and the water source/quality of your system. Filtering is the standard practice used to minimize sediment clogging problems.

Choosing the appropriate filtration system, or improving your existing filter station to ensure it is working effectively, is important for keeping your irrigation system clean and ensuring the distribution uniformity remains high. The following points outline recommendations to consider when selecting and/or maintaining a filtration system for surface or groundwater use.

Appropriate filtration can help to extend the life and improve the maintenance of an irrigation system. For drip or micro sprinklers emitters, filtration is a basic need to avoid clogging. A sand grain, rust and other materials can block micro and mini sprinklers nozzles which may cause unintentional plants dehydration. Many water sources like reservoirs, rivers and of course waste water contain a lot of organic materials such as alga and bacteria, that have to be removed especially from drip irrigation, mist spray and micro-sprinkle systems, as small as they are. Not removing those substances can lead to dirt accumulation and colonies of harmful material within the emitters & rest of the equipment. Naturally, rust and sand grains are a safe platform for coating by organic materials and creating large chunks within the systems, causing a total blockage of water transferring.

One of the most important elements of an irrigation system that draws its water supply from a non-potable source is the filtration. Proper filtration is critical to protect all components of the system: from the pump to the emission devices. Proper selection of a filter involves taking into account the types of contaminants found in the source water, the frequency and availability of maintenance service to the filter, and the type of emission devices used in the irrigation system. A properly selected and installed filtration system will protect your irrigation system.

System Requirements – What type of Irrigation Equipment/What type of Water?

A Filtration system should be designed to answer the irrigation system needs as to the required cleanliness (filtration degree) in view of the prevailing water quality at the irrigation head. Filtration is recommended to ensure adequate water cleanliness in order to keep the systems high distribution uniformity. Pressurized irrigation systems have emitters, which are prone to clogging. As per the sensitivity of the system, systems water filtration degree is divided into three categories:

- For Pivot/linear irrigation systems: 300-800 micron

- For micro sprinkler systems: 130 micron

- For drip tapes: 80 – 130 micron

Water quality is derived from its source:

- Well water have: sand particles and in many cases sulphur compounds.

- River water have: high load or suspended solids, organic matter.

- Lake and reservoirs have: high loads of organic matter (dead or alive).

Today a matured product range is offered by Automat in filtration systems.

Selection of filter is divided into three categories:

- Kinetic separation or hydrocyclone

- Surface filtration or Screen

- Disc filter: combination of screen and depth.

HYDROCYCLONE:

Using a simple yet clever design of a conical casing with a tangential inlet, suspended particles which have density higher then water is thrown outward by centrifugal forces where they meet the casing perimeter and sink to the bottom where either a drain valve to allow flushing or a small chamber to increase the filter capacity. It is installed where water contains sand, mostly in well water. The Automat have 2”, 2.5” & 3” connection size hydrocyclone in high grade engineering plastic with added UV resistance for long life. This can be used as per system requirement and line flow rates.

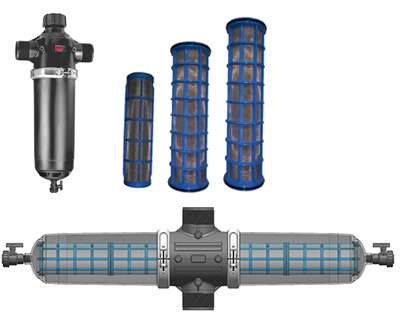

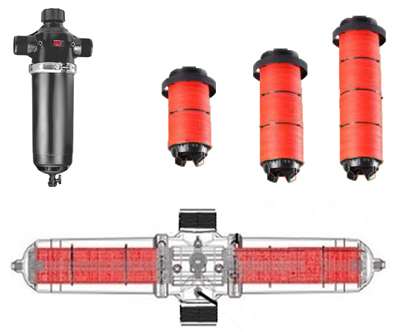

SCREEN FILTER:

made of plastic supported by a perforated frame. Water passes through the screen and particles can be intercepted by the screen. Such filters are generally not recommended for filtering out organic matter such as algae and do not have the capacity to filter large amounts of contaminants. The Automat have 2”, 2.5”, 3” & 4” connection size screen filters in high grade engineering plastic with added UV resistance for long life with availability of 80, 120, 150 mesh size screen element. This can be used as per system requirement and line flow rates.

DISC FILTERS:

Polymer disc have groove on both sides in a special way, pile and compress them together, we get a three dimensional structure consisting of multiple screens allowing depth filtration of water coming from the outside disc cylinder. Due to their unique structure, disc filters can be used to clean low loads of organic material.

- Selection of filters by keeping irrigation system and water quality in mind. Hydrocyclone should be used with sand particles load. Suspended solids of a finer fraction as well as high organic load should be tackled by media filters while low organic load should be taken care of by disc filtration. Last, self-cleaning screen filters can deal with almost anything.

- Hydraulics of Filtration: If flow rates is too high, rapid build-up of contamination occur, to eliminate this system should be equipped with self-cleaning mechanism. Low pressure is also a problem as insufficient pressure to clean the filter by back flushing.

An irrigation system that uses subsurface water, or groundwater, must deal with different impurities to those found in water from surface sources, such as mineral substances. A high level of minerals can clog your irrigation system on two fronts. Clumped sand from well water can physically clog your system, and chemical interactions among minerals like magnesium, hard water and fertilizers, can also increase the chances of clogging.

Unfiltered well water can wreak havoc on agricultural profitability and yield. Some of the problems that can result from using unfiltered or inadequately filtered water in your irrigation system include:

- Clogged emitters, resulting in uneven irrigation and reduced yield and/or plant damage or loss.

- Pump Failure.

- Stuck or poorly functioning valves.

- Reduced pressure in the system, which can cause myriad issues including damage to the system and/or inadequate water distribution.

There is more than one way to protect your irrigation system from clogging, but the best way is to prevent it. A good water filtration system will save you time and money.

One option is semi-automatic cleaning screen & Disc filters. These have been improved and upgraded to provide high quality and reliable filtration, protecting all types of irrigation system. These filters use suction-scanning technology to clean the screens.

FILTER DURABILITY

What is the filter housed in? Does it use screen/disc filters? The best screen/disc filters have a corrosion free polymer housing and internal parts. Combined with semi-automatic cleaning technology, these polymeric filters offer long-term durability. For options including higher flow rates screens, you are ensured a better filtration system. Both coarse and fine screens are effective for filtering and can be flushed.

WATER & POWER CONSUMPTION

It’s crucial that the filter you choose is cost effective. Durable water filtration systems with semi-automatic cleaning mechanisms are cost-effective as they decrease downtime and use less water and power. Water filters that use a hydraulic turbine methodology generally use less power, which can save money.

CAN IT HANDLE LOW PRESSURE?

The last thing you want is vacuum formation and other disruptions in your water filtering system. Most semi-automatic filters require a minimum of 2 bar or 30 psi for proper cleaning of the filter element by focusing on these factors, you will find a water filter for your irrigation system that not only knows how to handle the clogging factors found in well water, but is also low maintenance, cost-effective and user friendly.

Filters can help extend the life of, and lower the maintenance on, your sprinkler system. For drip systems they are a necessity to prevent emitters from becoming plugged. Even if small sand particles can pass through your system without clogging it, they cause wear on the equipment.

Automatic valves contain very small water passageways which can become plugged resulting in the valve failing to either open or close. A small grain of sand caught in a spray nozzle can result in a dry and dead spot in a lawn. While sand is probably the first thing most people think needs to be filtered out of the water, organic materials can be just as important to remove. Algae can grow inside the system, especially in drip tubes. Another situation occurs when a small piece of organic matter snags somewhere in a valve, fitting, emitter, or sprinkler. The organic matter by itself may not be large enough to be a problem. But soon another piece comes along and gets caught. Then a very small grain of sand that would normally have passed through the system without problems gets caught by the organic matter. Soon a large build-up of crud forms and the flow is blocked. Have you ever had the hose on your vacuum cleaner clog up with a wad of hair, small objects, and dirt? Each one of those objects went into the hose, so they should have made it through to the canister. But they did not because they all got caught together. The same thing happens in irrigation system.

So which filter to use? There is no fixed answer. Your budget, water quality, and availability of the filter and parts must all be considered. Screen filters are generally the least expensive. If you have a city water supply with nothing more than a periodic grain of sand of flake of rust in it, a screen filter will be fine in most cases. Sometimes a combination of more than one type of filter will be needed. For a smaller size system a disk filter would remove both sand and organics, but you might need to frequently clean it! Here are some suggestions based on the source of your irrigation water.

Correct installation of the system is often overlooked. Appropriately skilled staff should install the system. This will ensure reliable system operation. You need to make sure that all products meet appropriate standards and that all construction complies with regulations, standards and design. When a system is installed an ‘as installed’ plan should be provided, as should operating instructions for all serviceable products used (e.g. pumps and filters).

Correct maintenance is the key to the system long term operation and efficiency. Correct maintenance should include: Filtration. Monitor pressure differential, annual disassembly and check moving parts for wear.