You must have heard about Air Valves – but do you know what is it used for? What are its functions? How to install or use it? Read on – for a blog post will share all this and more.

What are Air Valves?

Every irrigation system consists of pipes that carry water from its source to its destination. In this process and often due to erratic water supply levels – pockets of trapped air can form in these pipelines. This trapped air can affect the life and of water pipelines and overall system performance.

We, therefore, use Air Valves to overcome this problem. Air Release Valves help in ejecting trapped air, which ensures the smooth flow of water in the pipelines and smooth functioning of the irrigation system. This happens when the Air Release Valve opens up against the internal pressure built up inside the water pipe.

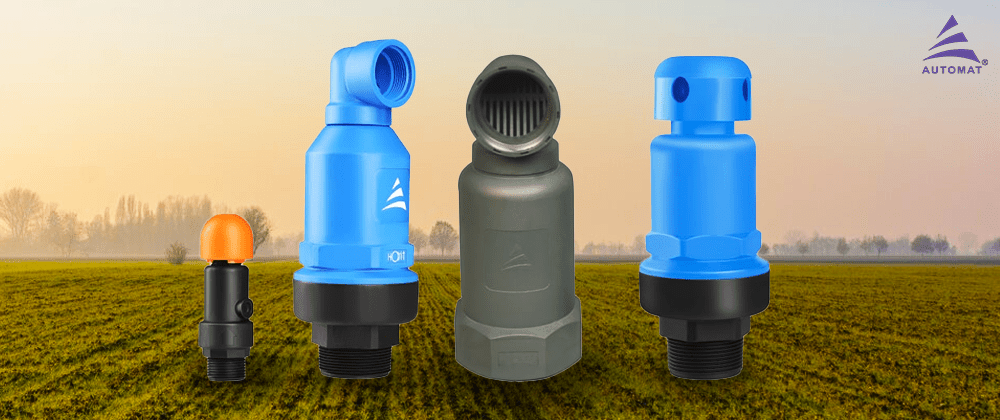

This happens because of the internal lever mechanism that increases the float force. This force further opens the vent whenever air gets trap in the system. Our Air Valves are a product of aluminium, brass and engineering plastic. So they can easily withstand the effects of continuous water flow and deliver on heavy-duty performance parameters.

Read More: Know the Ways to Set the Pressure Relieve Valve

Functions of Air Valves

There are three major functions of air valves.

- Stopping and starting the flow of water

If the water system does not require the throttle flow of water – then one can use valves for starting and stopping the flow of water.

- Throttling the flow of water

Throttling the flow is all about reducing the flow of water as required. The main use of the valve is to reduce the pressure of the water in the system.

- Maintaining water flow in the right direction

This is another very important function of the valves. Maintaining water flow in the right direction is crucial for the proper functioning of the system. Valves open up when the flow is in the right direction and shut down when the water flow is in the reverse direction. Thus valves are immensely useful as they prevent backflow of water.

Types of Air Valves

Wide ranges of valves are available in the market. We shall discuss the three most commonly used types of valves, their benefits, and limitations.

- Air Release Valve

The most widely used type of Valve is Air Release Valve. It consists of small cavities, heavy floats, and a leverage apparatus. All these features work together and enable the air release valve to expel trapped air with full force.

The thickness of the cavity in the Air Release Valve can vary widely. They can range somewhere in between 1/15” to 1”. Since cavities or vents have limited ability to expel large volumes of trapped air – Air Release Valves eliminate small pockets of collected air from a piping system.

When Air Release Valves are to be mount – they are usually open. It is only after the water passes through the Valve, the float rises. This happens because of its resilience and lids that cover Valve’s cavity. Once operational and as air gathers in the Valve frame, the float will fall due to its weight.

- Air/ Vacuum Valve

An Air/ Vacuum Valve has a full-size vent. The size may vary from ½” to 25”. Due to their large size – they can expel a large volume of air. Similarly, they are also capable of intake of a large volume of air. This further helps to avoid the creation of a vacuum in the pipeline.

Air or Vacuum Valves are usually open and afloat in the valve and they rise with the water level to seal the large cavity after the air expels out.

On the other hand, when system compression is low because of draining, the float drops and lets the air re-enter the pipeline.

Air or Vacuum Valves do not have a power connection. Further because of the large diameter of their cavity, they do not open in when in a pressurized state. For this reason, an Air Release Valve is necessary for discharge air and gas during the irrigation system operation.

Air/Vacuum Valves are in wide use for the release of air especially when working with vertical turbine pumps. This is because, after the closure of the valve, the pipeline between the thrust and the check valve gets filled with air.

A vertical turbine, when turned on quickly, uplifts a heavy amount of water. So the air pocket should exhaust before the water can open up the check valve. Thus – an air/vacuum valve is the right fit for this use as it can quickly eject large volumes of trapped air.

One should install Air/Vacuum Valve at the top of the thrust column. It is necessary to do so because when the pump starts, the accumulated air tends to get out of the air vacuum valve. Valves are often armed with a throttling device – which is adjustable and fitted on top of the valve to regulate the flow of air expulsion.

Since the water pump can pick up full speed in a few minutes, you can use the throttling device to bring down the rate of air expulsion, ensuring the water flow and its speed is not too fast – else it will affect the downstream check valve, causing water sledgehammer in the pump column.

A slow closing device is another option used for Air/ Vacuum valve. The slow-closing device is generally in use for pipe applications where column parting may happen.

Another function of this device is to shut the valve when the expulsion rate increases. The slow-closing device can be fixed on the creek of clean water valves and the outlet of wastewater air valves for optimum results.

- Combination Air Valve

A Combination Air Valve is the third most common type of valve. It is known as Combination Air Valve because it has features of both the Air Release Valve and an Air/Vacuum Valve. The Combination Air Valve is usually equipped with a single body design, which consists of air release and air/ vacuum components.

It is also available in dual body design, in which an air release valve is piped into the side of an air/vacuum valve. The two arrangements perform the same tasks.

Though the single-body design can be more cost-effective – the dual-body design can offer design flexibility when sizing the vents. Some piping designers use a combination air valve on a pipeline because all valves functions are part of it.

Best Ways to Install Air Valves

One of the best ways to install them is to fix them at the top of the pipeline. several people lay pipes under the ground or below the soil – so the valves in some cases need a separate vault.

It such cases it is very important for connecting pipes to be the proper size for water flow conditions. Besides, stretched air valve piping can have varying effects on water surge levels, so analysis may require to gauge piping requirements.

Including a shutoff valve under the air, the valve is very crucial for maintenance purposes. Similarly, a riser pipe larger than the air valve creek is what we suggest to assist the air allowance in the valve that runs along the pipeline. You can use the ditch valve once a year to check the utility of the air valve.

If the ditch valve ejects air, the air release part of the valve may require repairs or maintenance. Else, you should check the air valve – during a pump operation to monitor the rate at which it is expelling air without unnecessary seepage.

Location

With regard to the location/ position of an Air Valve – since its primary function is to release the unwanted pockets of air from a pipeline – it functions effectively only when appropriately positioned. The location or positioning depends upon the size of the Air Valve.

We would recommend you to install Air Valves at those points where the pipeline is most susceptible to a sub-atmospheric pressure. The proper location of the Air Valve can improve water flow performance significantly.

Maintenance and Repair

reviewing or carrying out repairs on an air valve requires a lot of care. This is because when a system is functioning, an air valve can release large quantities of air under pressure or admit large quantities of air under vacuum conditions.

Both can cause bodily harm. Any maintenance on an air valve requires closing the shutoff valve under the air valve. But even with the shutoff valve closed, it can trap pressurised air in the air valve.

You can check out our the extensive range of Safety Valves here

An integral part of any micro-irrigation or drip irrigation system – Automat’s Safety Valves are specially designed from durable engineering polymer, aluminium, and brass and are used to remove trapped air and remove the vacuum in the system.

Thus you can operate your system at maximum operating pressure while avoiding broken pipes and damage to your system.

In case of questions about our quality irrigation systems and solutions, please email our team on marketing@automatworld.com or WhatsApp us on +91-9871999458. Our representatives will get back to you within the shortest time possible.